Los paquetes de baterías comunes generalmente utilizan tres métodos de enfriamiento: enfriamiento líquido, enfriamiento por aire y enfriamiento natural. Celdas de batería Son bastante sensibles a la temperatura, con una temperatura óptima de funcionamiento generalmente entre 15 y 35 °C. Las variaciones de temperatura provocan distintos grados de reducción de la capacidad en las baterías de litio; en concreto, a -10 °C, la capacidad útil es del 70 %; a 0 °C, del 85 %; y a 25 °C, del 100 %. Entre estos tres métodos principales de refrigeración, la refrigeración natural es lenta, ineficiente y difícil de controlar la temperatura de las celdas, lo que no cumple con los requisitos de disipación de calor de los sistemas actuales de almacenamiento de energía compuestos por celdas de gran capacidad. Por lo tanto, el mercado actual de almacenamiento de energía utiliza principalmente paquetes de baterías refrigerados por líquido.

Antes de profundizar en los paquetes de baterías, comprendamos los conceptos de celda, paquete de baterías y pila de baterías.

Primero, vamos a presentar la célula: Una celda es esencialmente una sola celda de batería, el componente principal de una batería y el elemento más básico en paquetes de baterías y pilas. Normalmente proporciona un voltaje entre 3 V y 4 V.

Una celda de batería es una unidad sellada e independiente que conecta electrodos positivos y negativos, generalmente fabricados con materiales como baterías de iones de litio, níquel-hidruro metálico o plomo-ácido. Cada celda incluye un electrodo positivo, un electrodo negativo y separadores para garantizar que no haya contacto electrónico directo entre ambos.

Células de batería de iones de litio Se envasan principalmente en dos categorías según su carcasa: rígida y tipo bolsa. La carcasa rígida utiliza principalmente carcasas de acero y aluminio, y se divide en formas cilíndricas y prismáticas según la disposición de los electrodos positivo y negativo. El tipo bolsa utiliza principalmente una película de aluminio y plástico. Gracias a los continuos avances en la tecnología y los procesos de envasado, los métodos de envasado cilíndrico, prismático y tipo bolsa han alcanzado un equilibrio tripartito.

Estos tres métodos de embalaje corresponden a tres métodos de bobinado para baterías de iones de litio: las baterías de iones de litio cilíndricas corresponden al bobinado cilíndrico, las baterías de iones de litio prismáticas al bobinado prismático y las baterías de iones de litio en bolsa al bobinado prismático apilado.

Entre ellas, las baterías cilíndricas presentan las ventajas de una mayor eficiencia y un menor coste de producción, mientras que sus desventajas se centran principalmente en una densidad energética unicelular relativamente menor y en la seguridad. Las baterías de paquete blando utilizan un embalaje de película de aluminio y plástico, ofrecen buena seguridad, son más ligeras que las baterías con carcasa de acero y aluminio, presentan mayor energía específica, menor resistencia interna y una vida útil más larga. Sin embargo, debido a la gran cantidad de modelos, la baja automatización, la baja eficiencia de producción, el alto coste, la alta dependencia de películas de aluminio y plástico importadas de alta gama y su baja consistencia, son menos adecuadas para estos productos.

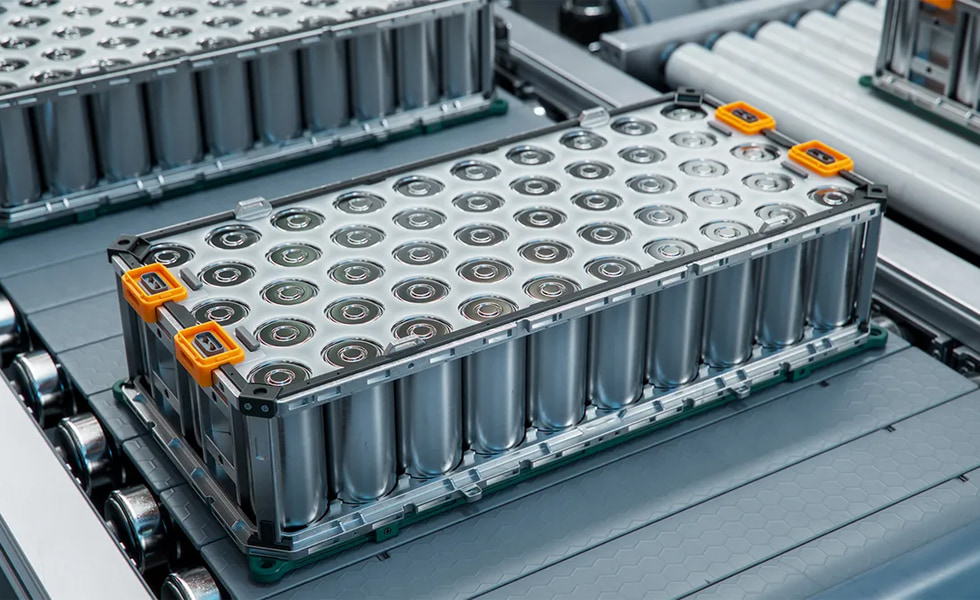

Paquetes de baterías: Compuesto por múltiples celdas de batería, formando un único módulo físico que proporciona mayor voltaje y capacidad (por ejemplo, un módulo de batería que utiliza cuatro celdas conectadas en serie para proporcionar un voltaje nominal de 12 V, o múltiples celdas conectadas en paralelo para proporcionar mayor capacidad).

Paquetes de baterías: Generalmente se componen de varios paquetes de baterías y también están equipados con un sistema de gestión de baterías (BMS), que es el producto final que el fabricante de la batería proporciona al usuario. Esto es lo que comúnmente se conoce como baterías de litio.

El proceso de empaquetado de baterías de litio consiste en empaquetar, ensamblar y probar las baterías de litio, y es una parte indispensable de su fabricación. Su importancia radica en que, mediante este proceso, las celdas de la batería, las placas de protección, los circuitos y otros componentes se pueden ensamblar para formar una unidad completa. producto de batería de litio , garantizando así la seguridad, confiabilidad y estabilidad del rendimiento de la batería de litio.

Un paquete incluye la batería, la barra colectora, la conexión flexible, la placa de protección, el embalaje exterior, la salida (incluidos los conectores) y materiales auxiliares como cartón y soportes de plástico. El proceso de ensamblaje de la batería es un paso crucial en su producción, lo que afecta directamente la seguridad y la fiabilidad de las baterías de litio. Los frecuentes incendios y explosiones de baterías de litio, que han causado lesiones en los últimos años, se deben principalmente a un diseño inadecuado de la batería, a la falta de una manipulación oportuna y una detección temprana de las celdas de litio individuales, o al sobrecalentamiento de la carcasa.

Requisitos y características del PACK:

① Los paquetes de baterías requieren una alta consistencia en las características de la batería (capacidad, resistencia interna, voltaje, curva de descarga, vida útil).

② El ciclo de vida de un paquete de baterías es menor que el de una sola celda.

③ Debe utilizarse en condiciones definidas (incluida la corriente de carga y descarga, el método de carga, la temperatura, etc.).

4. Una vez ensamblado el paquete de baterías de litio, el voltaje y la capacidad de la batería aumentan significativamente, lo que requiere protección mediante ecualización de carga, temperatura, voltaje y monitoreo de sobrecorriente.

⑤ El paquete de baterías debe cumplir con los requisitos de voltaje y capacidad diseñados.

Métodos PACK:

① Montaje en serie-paralelo: Las baterías se ensamblan a partir de celdas individuales conectadas en paralelo y en serie. La conexión en paralelo aumenta la capacidad sin cambiar el voltaje, mientras que la conexión en serie duplica el voltaje sin cambiar la capacidad. Por ejemplo, una batería de 3,6 V/10 Ah se compone de 5 celdas N18650/2 Ah conectadas en paralelo. Conexión en paralelo seguida de conexión en serie: Las diferencias en la resistencia interna y la disipación de calor desigual en la conexión en paralelo pueden afectar el ciclo de vida de las baterías. Sin embargo, si falla una sola celda, se desconecta automáticamente y, aparte de una reducción de capacidad, no afecta el uso de la conexión en paralelo. Los procesos de conexión en paralelo son más estrictos. Un cortocircuito en una sola celda en una conexión en paralelo puede causar una corriente muy alta en el circuito paralelo, que generalmente se previene agregando tecnología de protección por fusible. Conexión en serie seguida de conexión en paralelo: Las baterías se conectan primero en serie de acuerdo con la capacidad total del paquete de baterías. Por ejemplo, si 1/3 de la capacidad total está conectada en paralelo, entonces se conecta en paralelo al final, lo que reduce la probabilidad de falla en paquetes de baterías de gran capacidad.

② Requisitos de las celdas: Seleccione las celdas según sus requisitos de diseño. Las baterías conectadas en paralelo y en serie deben ser del mismo tipo y modelo, con diferencias de capacidad, resistencia interna y voltaje que no superen el 2 %. Generalmente, tras combinar baterías en paralelo y en serie, la pérdida de capacidad es del 2 % al 5 %, y cuantas más baterías haya, mayor será la pérdida. Tanto si se utilizan celdas tipo bolsa como cilíndricas, es necesario conectar varias celdas en serie. La falta de consistencia afecta la capacidad de la batería; la celda de menor capacidad de un grupo determina la capacidad total del grupo. Se requiere un alto rendimiento de descarga de alta corriente. La corriente de arranque de un motor es tres veces su corriente de funcionamiento normal; la descarga de alta corriente mejora el rendimiento del motor. Una buena disipación del calor también es esencial. Con un gran número de celdas, el aumento de temperatura dentro del paquete de baterías es difícil de disipar, lo que resulta en una distribución desigual de la temperatura y características de descarga inconsistentes, lo que en última instancia conlleva una degradación del rendimiento. Se requieren procesos de fabricación de alta calidad. Las baterías deben soportar vibraciones e impactos de carreteras con baches. Se exigen altos estándares en los procesos de fabricación, especialmente en la soldadura por puntos. Se realizan pruebas después de soldar para evitar una soldadura deficiente o desprendimiento.

③ Proceso de empaquetado: El empaquetado de la batería se logra de dos maneras: una es a través de soldadura láser, soldadura ultrasónica o soldadura por pulsos, métodos comúnmente utilizados con buena confiabilidad pero reemplazo difícil; la otra es a través de contacto metálico elástico, que elimina la necesidad de soldadura y facilita el reemplazo de la batería, pero puede provocar un contacto deficiente.

Proceso de fabricación de paquetes de baterías

01. Carga y clasificación celular

Inspección de celdas: En el proceso de fabricación de baterías de almacenamiento de energía, el primer paso es la inspección de las celdas. Las celdas son los componentes principales de las baterías de almacenamiento de energía y su rendimiento afecta directamente el rendimiento y la vida útil de la batería. Por lo tanto, la inspección de celdas es un paso crucial. El primer paso en la línea de producción consiste en realizar pruebas rigurosas de las celdas, que incluyen parámetros como el voltaje, la resistencia interna y la capacidad. Las celdas calificadas se clasifican según sus parámetros de rendimiento para garantizar la consistencia en cada paquete.

Clasificación: Antes de ensamblar las celdas para formar paquetes de baterías, es necesario clasificarlas según diferentes parámetros. Esto garantiza que las diferentes celdas, al combinarse en un grupo, tengan un rendimiento similar, mejorando así el rendimiento general y la vida útil del paquete de baterías.

02. Apilamiento de celdas

Las células que superan el cribado y las pruebas iniciales se transportan a la estación de apilado. Aquí, los trabajadores las clasifican y las fijan mediante separadores y placas terminales.

03. Despliegue del módulo

Los módulos celulares apilados se transportan a la línea de ensamblaje PACK, listos para el siguiente proceso. Se someten a rigurosas inspecciones para garantizar que cumplen con los requisitos de producción.

04. Direccionamiento CCD previo a la soldadura

Antes de soldar, se utiliza un sistema CCD para el direccionamiento. Este paso garantiza la correcta disposición de las celdas, proporcionando un posicionamiento preciso para la soldadura posterior.

05. Soldadura e inspección

A continuación, se realiza la soldadura para garantizar una conexión sólida y fiable entre las celdas. Tras la soldadura, se realizan pruebas exhaustivas, que incluyen parámetros como capacitancia, voltaje y corriente, para garantizar la calidad y el rendimiento del módulo.

06. Protección e Instalación

Para proteger las celdas individuales de la sobrecarga o la sobredescarga, se instalan placas de protección. Los conectores y cables se conectan al módulo para su conexión a otros sistemas.

07. Pruebas y desmantelamiento de módulos

Finalmente, el módulo se somete a una prueba de fin de vida útil (EOL) para garantizar que su calidad y rendimiento cumplan con los requisitos. Tras superar la prueba, el módulo se desmantela y queda listo para el siguiente proceso o para su empaquetado y envío.

Contenido de la prueba del paquete de baterías

Una vez que el paquete de baterías completa la prueba del gabinete, normalmente se realizan los siguientes pasos:

1. Pruebas funcionales: Garantiza el correcto funcionamiento del paquete de baterías tras su montaje en la carcasa. Esto incluye pruebas de carga y descarga para verificar que el voltaje, la capacidad, la densidad energética y otros parámetros del paquete de baterías cumplan con los requisitos.

2. Pruebas de seguridad: Prueba el rendimiento de seguridad del paquete de baterías, incluidas pruebas de cortocircuito, pruebas de protección contra sobrecorriente y pruebas de temperatura, para garantizar que el paquete de baterías no provoque incendios, explosiones u otros accidentes de seguridad durante el uso normal.

3. Pruebas de adaptabilidad ambiental: Coloca la batería bajo diferentes condiciones de temperatura, humedad y vibración para probar su estabilidad y confiabilidad en diversas condiciones ambientales.

4. Pruebas de confiabilidad: Realiza pruebas de ciclos de carga y descarga a largo plazo en el paquete de baterías para simular la vida útil y la confiabilidad en condiciones de uso reales.

5. Evaluación general del desempeño: Evalúa exhaustivamente los resultados de las pruebas anteriores para determinar si la batería cumple con los requisitos de diseño y realiza los ajustes y mejoras necesarios.

6. Preparación previa a la comercialización: Si la batería supera todas las pruebas y evaluaciones, puede prepararse para su comercialización. Esto incluye la certificación del producto, la elaboración de los manuales del producto y el diseño del embalaje.